After helping over 300 clients choose window treatments, I’ve noticed that double roller blinds[^1] create the most confusion among distributors and contractors. The concept seems straightforward, but the technical specifications and installation requirements often surprise buyers who expect simple single-blind solutions.

Double roller blinds combine two independent fabric panels in one mounting system, typically pairing light-filtering and blackout materials[^2] for versatile light control. This dual-functionality system costs 40-60% more than single roller blinds but delivers superior flexibility for spaces requiring both privacy and natural light options.

My experience with VelaBlinds has taught me that successful double roller blind projects require careful planning around functionality, installation complexity, and long-term value considerations that many buyers initially overlook.

Are double roller blinds worth it?

The value proposition for double roller blinds depends entirely on specific functional requirements and usage patterns rather than general cost-benefit assumptions[^3].

Double roller blinds justify their 40-60% price premium for spaces requiring frequent transitions between privacy and natural light, particularly bedrooms, media rooms, and offices with varying daily lighting needs. Single-function spaces rarely benefit from the additional complexity and cost.

Comprehensive Value Analysis for Professional Buyers

Based on extensive project tracking and client feedback, I’ve developed specific criteria for determining when double roller blinds deliver genuine value.

High-Value Applications:

- Master bedrooms requiring complete blackout for sleep and light filtering for daytime privacy

- Home offices needing glare control during work hours and blackout for video conferencing

- Media rooms balancing ambient lighting for casual viewing and complete darkness for movie experiences

- Commercial spaces with varying meeting requirements throughout daily cycles

Performance Advantages Over Single Systems:

- Eliminates need for secondary window treatments, reducing total installation costs

- Single mounting system requires less wall space than dual installations

- Coordinated aesthetic appearance maintains design consistency

- Independent operation allows precise light control customization

ROI Analysis Framework:

Initial investment typically ranges $120-180 per square meter versus $65-95 for single roller blinds. Value calculation must include eliminated secondary treatment costs, installation labor savings, and operational flexibility benefits.

Critical Decision Factors:

| Application | Single Roller Adequate | Double Roller Beneficial | Decision Rationale |

|---|---|---|---|

| Guest Bedrooms | Yes | No | Infrequent use doesn’t justify premium |

| Master Bedrooms | No | Yes | Daily light control variations essential |

| Kitchens | Yes | No | Single function sufficient |

| Home Offices | Maybe | Yes | Task lighting requirements vary |

For spaces with consistent lighting requirements, single roller blinds provide better value. Double roller systems excel when functionality justifies the premium investment through measurable convenience and performance improvements.

What are double roller blinds called?

Industry terminology varies by manufacturer and region, but several standard names describe the same dual-fabric roller system concept.

Double roller blinds are commonly called dual roller shades, twin roller blinds, or double-layer roller systems depending on manufacturer and regional preferences. All terms describe identical functionality—two independent fabric panels operating within a single mounting bracket system.

Professional Terminology and Market Standards

My work with international suppliers and distributors has revealed consistent functionality despite varying naming conventions across different markets.

Common Industry Names:

- Double roller blinds (most common in commercial specifications)

- Dual roller shades (preferred residential terminology)

- Twin roller systems (manufacturer technical specifications)

- Double-layer roller blinds (architectural specification language)

- Combo roller blinds (simplified marketing terminology)

Technical Specification Language:

Professional specifications typically reference "dual fabric roller systems" to distinguish from layered cellular or roman blind constructions. This terminology ensures accurate product sourcing and avoids confusion with other multi-layer window treatment types.

Regional Variations:

North American markets prefer "dual roller shades" while European specifications commonly use "double roller blinds." Australian markets frequently specify "twin roller systems." Understanding regional preferences helps ensure accurate communication and product delivery.

Manufacturer-Specific Terms:

Major suppliers like those available through VelaBlinds maintain consistent "dual roller shades" terminology in their product catalogs. This standardization simplifies specification and ordering processes for distributors and contractors.

Regardless of terminology used, functional specifications remain identical—two independent fabric panels, separate control mechanisms, and single mounting system[^4] integration.

What is a double roller shade?

Double roller shades represent an engineered solution combining two independent roller mechanisms within a unified mounting and control system.

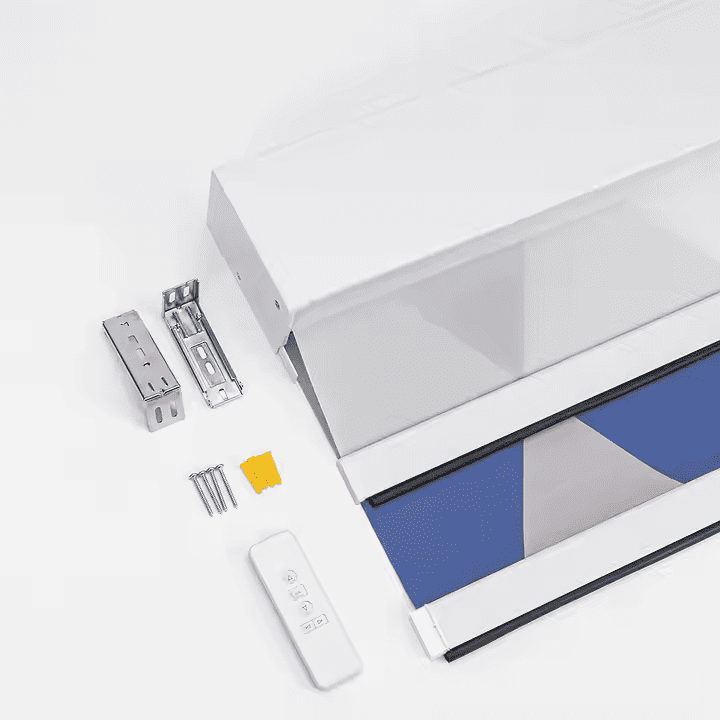

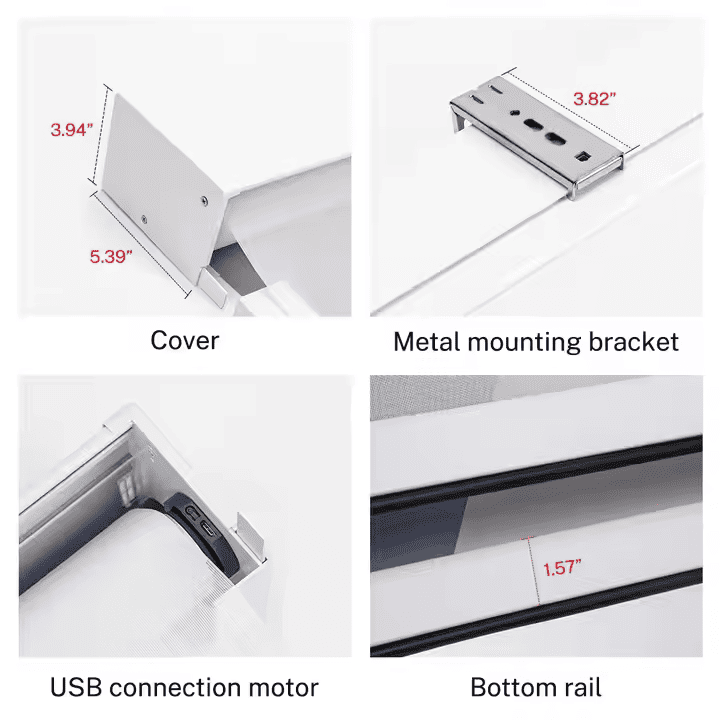

A double roller shade consists of two separate fabric panels—typically light-filtering and blackout materials—mounted in a single bracket system with independent operation controls. Each fabric panel operates on its own roller tube, allowing selective deployment for customized light control.

Technical Construction and Operational Analysis

My technical evaluation of double roller shade systems reveals sophisticated engineering required for reliable dual-fabric operation.

Core Components:

- Dual roller tubes (typically 32mm diameter each) housed within enlarged mounting brackets

- Independent spring tension or motorized systems for each fabric panel

- Coordinated control mechanisms enabling synchronized or independent operation

- Fabric guides preventing panel interference during operation

Fabric Panel Specifications:

- Front panel: Usually light-filtering material (3-10% openness factor)

- Rear panel: Blackout or room-darkening fabric (99% light blockage)

- Panel width coordination ensures proper overlap and gap elimination

- Fabric weight balancing prevents operational binding or uneven rolling

Operational Modes:

- Independent deployment allows single fabric use for specific lighting needs

- Layered operation combines both fabrics for intermediate light control

- Full deployment provides maximum privacy and light blockage

- Partial positioning enables precise light management throughout daily cycles

Installation Considerations:

- Mounting depth requirements 20-30% greater than single roller systems

- Weight distribution demands robust bracket support, especially for motorized versions

- Precision alignment critical for smooth dual-fabric operation

- Electrical requirements increase significantly for motorized dual systems

Understanding these technical specifications helps ensure proper specification and successful installation outcomes for professional applications.

Do I need double roller blinds?

The necessity for double roller blinds depends on specific functional requirements, usage patterns, and space constraints rather than general preferences or trends.

Double roller blinds are necessary when spaces require frequent transitions between privacy and natural light throughout daily cycles, particularly bedrooms, offices, and multi-function rooms. Single-purpose spaces rarely justify the additional complexity and investment.

Systematic Needs Assessment for Professional Specification

Through detailed client consultation and post-installation feedback, I’ve developed a systematic approach for determining double roller blind necessity.

Essential Requirements Checklist:

Daily Light Control Variations:

- Morning privacy needs with afternoon natural light preferences

- Work-from-home requirements alternating between glare control and blackout for video calls

- Entertainment spaces requiring ambient and complete darkness options

- Bedroom applications balancing sleep requirements with daytime functionality

Space Functionality Analysis:

- Single-purpose rooms (storage, utility) typically don’t require dual functionality

- Multi-function spaces (guest room/office combinations) often benefit from flexibility

- High-traffic areas with varying occupancy patterns throughout daily cycles

- Spaces with specific task lighting requirements changing throughout day

Alternative Solution Evaluation:

- Could layered window treatments (curtains + blinds) achieve similar results?

- Would smart lighting integration eliminate need for variable natural light control?

- Can room usage patterns be modified to work with single-function window treatments?

- Are there architectural solutions (interior partitions, lighting design) providing better alternatives?

Cost-Benefit Decision Matrix:

| Space Type | Dual Function Benefit | Cost Justification | Recommendation |

|---|---|---|---|

| Master Bedroom | High | Strong | Double roller recommended |

| Guest Bedroom | Low | Weak | Single roller adequate |

| Home Office | High | Strong | Double roller beneficial |

| Kitchen | Low | Weak | Single roller sufficient |

| Media Room | Medium-High | Moderate | Consider double roller |

Professional Assessment Protocol:

- Document actual usage patterns over 1-2 week periods

- Identify specific times requiring different light control levels

- Evaluate alternative solutions for achieving similar functionality

- Calculate total cost including installation and long-term maintenance

- Compare projected convenience benefits against premium investment

This systematic evaluation prevents over-specification while ensuring adequate functionality for spaces that genuinely benefit from dual roller flexibility.

Can you put two roller blinds together?

Installing two separate roller blinds in close proximity creates operational and aesthetic challenges that double roller systems are specifically designed to address.

Two separate roller blinds can be installed together but create spacing issues, mounting conflicts, and aesthetic inconsistencies[^5]. Purpose-built double roller systems provide superior integration, coordinated operation, and professional appearance compared to dual single-blind installations.

Technical Analysis of Dual Installation Options

My experience with various dual installation approaches reveals significant advantages for integrated double roller systems over separate blind installations.

Separate Blind Installation Challenges:

- Mounting bracket spacing requires minimum 4-6 inches between systems

- Fabric overlap coordination difficult without precise measurement and alignment

- Independent control mechanisms create operational complexity

- Aesthetic inconsistency from varying fabric positions and alignment issues

Professional Installation Requirements:

- Structural support analysis required for dual mounting loads

- Precise measurement critical for proper fabric overlap without binding

- Electrical complexity increases for dual motorized systems

- Installation time typically 60-80% longer than single or integrated double systems

Performance Limitations:

- Gap elimination between fabrics nearly impossible with separate systems

- Light leakage occurs at fabric intersection points

- Uneven operation common due to independent spring tension or motor calibration

- Maintenance complexity doubles with separate cleaning and adjustment requirements

Cost Comparison Analysis:

- Two separate roller blinds: $130-190 per square meter including dual installation

- Integrated double roller system: $120-180 per square meter with single installation

- Labor costs 40-60% higher for separate installations

- Long-term maintenance costs significantly higher for dual separate systems

Integrated Double Roller Advantages:

- Single mounting system reduces wall space requirements

- Coordinated fabric operation eliminates gaps and alignment issues

- Professional appearance with consistent fabric positioning

- Simplified maintenance and adjustment procedures

For professional installation[^6]s requiring dual-fabric functionality, integrated double roller systems provide superior performance, appearance, and value compared to separate blind installations.

How to overlap roller blinds?

Proper overlap technique is crucial for eliminating light gaps when using dual roller blind systems, whether integrated or separate installations.

Roller blind overlap requires precise fabric positioning with 1-2 inch minimum overlap zones, front fabric extending beyond rear fabric edges, and careful bracket alignment to prevent binding. Professional installation ensures consistent overlap throughout operational range.

Professional Overlap Installation Methodology

Based on hundreds of successful dual roller installations, I’ve developed specific techniques ensuring consistent overlap performance.

Critical Measurement Requirements:

- Front fabric width: Window width plus 3-4 inches for adequate side coverage

- Rear fabric width: Window width plus 1-2 inches for structural overlap

- Bracket positioning: Front bracket 2-3 inches forward of rear bracket

- Overlap zone calculation: Minimum 1 inch fabric overlap at all operational positions

Installation Sequence Protocol:

- Install rear mounting bracket ensuring level placement and structural support

- Mount front bracket with precise 2-3 inch forward positioning

- Install rear roller blind and test full operational range

- Install front roller blind ensuring fabric clears rear fabric throughout operation

- Test overlap consistency at multiple deployment positions

Common Overlap Failures and Solutions:

| Problem | Cause | Solution |

|---|---|---|

| Light gaps at sides | Insufficient fabric width | Increase fabric overhang 1-2 inches |

| Fabric binding | Bracket misalignment | Re-position brackets with precise spacing |

| Uneven overlap | Installation not level | Re-install with proper leveling tools |

| Operation interference | Inadequate bracket spacing | Increase forward bracket positioning |

Quality Control Verification:

- Test overlap consistency at 25%, 50%, 75%, and 100% deployment positions

- Verify no light gaps visible from interior perspective

- Confirm smooth operation without fabric interference

- Document final measurements for future service reference

Professional Tools Required:

- Precision level (minimum 24-inch length)

- Measuring tape with 1/16-inch accuracy

- Drill with appropriate bits for mounting surface

- Stud finder for structural mounting point location

Proper overlap installation requires professional expertise and precision tools to achieve consistent, gap-free performance throughout the operational life of dual roller blind systems.

Why are roller blinds so expensive?

Roller blind pricing reflects sophisticated manufacturing processes, quality materials, precision engineering, and comprehensive service support rather than simple fabric costs.

Roller blinds command premium pricing due to precision manufacturing tolerances, motorization complexity, custom sizing requirements, and professional installation support. Quality systems require advanced materials and engineering that justify costs compared to basic window covering alternatives.

Comprehensive Cost Analysis for Professional Understanding

My analysis of roller blind pricing across multiple manufacturers and quality levels reveals specific factors driving costs above basic window treatment alternatives.

Manufacturing Complexity Factors:

- Precision tube straightness within 0.5mm tolerance prevents fabric bunching

- Spring tension calibration requires specialized equipment and testing

- Fabric bonding processes using ultrasonic welding prevent delamination

- Quality control testing includes 10,000+ operation cycle verification

Material Cost Components:

- Premium fabrics with UV-resistant treatments cost 3-4x basic materials

- Aluminum roller tubes require precision machining for smooth operation

- Mounting hardware engineered for specific load ratings and durability

- Control mechanisms (chains, cords, motors) represent 25-35% of total cost

Customization Requirements:

- Made-to-measure sizing eliminates inventory carrying costs but increases per-unit production expense

- Color matching and fabric selection expand manufacturing complexity

- Special treatments (fire retardation, moisture resistance) add processing steps

- Small batch production lacks economy of scale benefits

Professional Service Integration:

- Technical support and specification assistance

- Installation guidance and troubleshooting resources

- Warranty coverage and replacement part availability

- Quality assurance testing and certification

Price Comparison Context:

| Quality Level | Price Range (per sqm) | Target Market | Value Proposition |

|---|---|---|---|

| Budget | $45-65 | DIY residential | Basic functionality |

| Mid-range | $75-110 | Professional residential | Balanced quality/cost |

| Premium | $120-180 | Commercial | Superior durability/performance |

Value Justification Analysis:

Premium pricing reflects engineering excellence, material quality, and service support that justify investment through extended service life, superior performance, and reduced maintenance requirements. Quality roller blinds deliver 8-12 year service life versus 3-5 years for budget alternatives.

Understanding cost drivers helps distributors and contractors communicate value propositions effectively to clients while setting realistic budget expectations for different quality levels and application requirements.

What are the disadvantages of roller blinds?

Despite their popularity and functionality, roller blinds present specific limitations that must be considered during specification and client consultation processes.

Roller blinds offer limited light control positions, minimal natural ventilation when closed, fabric replacement complexity, and potential wind resistance issues for high-rise installations. Understanding these limitations ensures appropriate application and realistic client expectations.

Critical Limitation Analysis for Professional Planning

My extensive experience with roller blind installations has revealed consistent limitation patterns that affect project success and client satisfaction.

Operational Limitations:

- Binary light control—blinds operate primarily in fully open or fully closed positions

- Partial positioning creates uneven fabric stress leading to premature wear patterns

- No natural ventilation capability when privacy requirements mandate closure

- Limited view-through options compared to venetian or other adjustable systems

Installation and Environmental Challenges:

- Wind resistance limitations affect installations above 15th floor levels

- Moisture sensitivity in bathroom and kitchen applications requires careful fabric selection

- Mounting depth requirements may conflict with narrow window frames

- Motorization adds complexity and potential failure points

Maintenance and Service Issues:

- Fabric replacement requires complete system disassembly

- Stain removal difficulty varies significantly by fabric type and treatment

- Professional cleaning often costs 60-80% of replacement fabric price

- Repair complexity higher for motorized systems due to integrated components

Performance Limitations by Application:

| Environment | Primary Limitation | Impact Level | Mitigation Strategy |

|---|---|---|---|

| High-rise offices | Wind resistance | High | Specify heavy-duty hardware |

| Bathrooms | Moisture sensitivity | Medium | Select synthetic fabrics |

| Bedrooms | Light control precision | Low | Consider blackout fabrics |

| Kitchens | Cleaning difficulty | Medium | Avoid textured fabrics |

Long-term Ownership Considerations:

- Fabric fading accelerates in direct sunlight exposure

- Spring tension degradation affects operation smoothness over time

- Chain and cord systems require periodic adjustment and replacement

- Technology obsolescence for smart motorized systems

Professional Mitigation Strategies:

- Specify appropriate quality levels for specific applications

- Set realistic client expectations regarding limitations

- Plan maintenance schedules based on environmental conditions

- Consider alternative systems for applications where limitations create significant issues

Understanding these disadvantages enables better system selection and prevents specification errors that lead to client dissatisfaction.

Conclusion

Double roller blinds provide exceptional functionality for spaces requiring variable light control, but success depends on careful specification matching system capabilities to actual usage requirements and budget constraints.

Extended FAQ Section

How long do double roller blinds last compared to single roller blinds?

Double roller blinds typically last 8-12 years with proper maintenance, similar to quality single roller systems, but component complexity can reduce reliability. The dual-fabric system experiences different wear patterns, with the frequently used panel (usually light-filtering) requiring replacement 2-3 years before the secondary panel.

Motorized double roller systems show 10-15% higher failure rates due to increased mechanical complexity and higher power consumption requirements. Manual systems achieve comparable durability to single roller blinds when properly installed and maintained. Quality manufacturers provide 5-7 year warranties on double roller systems versus 7-10 years for single systems, reflecting the additional complexity and potential service requirements.

Can double roller blinds be repaired or do you need to replace the whole system?

Double roller blinds allow component-level repairs for most common issues, making them more serviceable than complete replacement requirements. Individual fabric panels can be replaced without affecting the secondary fabric or mounting system, typically costing 40-60% of original system price for single panel replacement.

Mechanical components including spring mechanisms, chains, and mounting brackets can be serviced independently. Motorization systems require specialized technical service but individual motor replacement costs $85-150 versus $200-350 for complete system replacement. Common repairs include fabric re-tensioning, bracket adjustment, and control mechanism replacement. Professional service availability varies by manufacturer, making supplier selection important for long-term serviceability and parts availability.

What’s the difference between double roller blinds and layered window treatments?

Double roller blinds integrate two fabrics in a single mounting system, while layered treatments combine separate window covering types like curtains over blinds. Double roller systems provide coordinated operation and consistent aesthetic appearance, while layered treatments offer greater design flexibility but require multiple installations and controls.

Cost comparison shows double roller blinds typically cost $120-180 per square meter installed, while layered treatments range $150-250 per square meter including both systems and dual installation labor. Double roller blinds require single mounting points and bracket systems, reducing wall space requirements and structural load. Layered treatments allow mixing different manufacturers and styles but create maintenance complexity and potential aesthetic conflicts. For professional installations prioritizing functionality and streamlined appearance, double roller blinds provide superior integration and long-term value.

Transform Your Projects with Professional Double Roller Blind Solutions

Stop struggling with complex window treatment decisions that impact project timelines and client satisfaction. Our technical specialists provide comprehensive double roller blind specifications, installation guidance, and ongoing support tailored to your specific project requirements.

Whether you need sophisticated light control for executive spaces or versatile functionality for modern residential developments, we deliver complete system solutions including technical documentation, 3D visualization, and professional installation support.

Get detailed specifications and project-specific recommendations from our window treatment experts today.

info@velablinds.com

---

[^1]: Explore the advantages of double roller blinds for versatile light control and privacy.

[^2]: Learn how these materials enhance comfort and functionality in window treatments.

[^3]: Evaluate the financial implications of investing in double roller blinds.

[^4]: Learn why a single mounting system is more efficient than dual installations.

[^5]: Understand the importance of cohesive design in window treatment installations.

[^6]: Understand the benefits of hiring professionals for optimal installation outcomes.Partner with VelaBlinds for Your Next Project

Smart window treatments shouldn’t be complicated. After working with 500+ distributors and contractors worldwide, I’ve streamlined the process to get you quality products, competitive pricing, and reliable support – every time.

Why project professionals choose VelaBlinds:

- ✅ Fast, Accurate Quotes – Detailed specs and pricing within 24 hours

- ✅ Transparent Pricing – No hidden fees, volume discounts clearly outlined

- ✅ Quality Assurance – Direct partnerships with certified OEM manufacturers

- ✅ Project Support – Dedicated account manager from quote to delivery

Start your next project:

📧 Quick Quote: Send your requirements to info@velablinds.com

📱 Direct Contact: WhatsApp +86 137 2012 8317

🌐 Browse Solutions: https://velablinds.com/

📁 Product Resources: Access spec sheets, catalogs & project files

Jimmy Chen, Founder

"I built VelaBlinds to solve the real challenges I faced as a project buyer – long lead times, unclear specs, and unreliable suppliers. Let’s discuss how we can power your projects with smarter blinds."

Serving distributors and contractors across North America, Europe, and Australia since 2018.