Energy costs escalate while buildings struggle with thermal efficiency. Standard window treatments provide minimal insulation value, creating significant energy waste and comfort issues in commercial and residential applications.

Thermal insulation standards for blinds measure R-values, air infiltration reduction, and energy performance through NFRC certification, with cellular and multi-layer designs achieving R-values of 2.0-6.0 for optimal thermal efficiency.

I’ve specified thermal performance requirements for over 300 energy-efficient projects across commercial and residential applications. Understanding insulation standards prevents costly energy waste and ensures optimal comfort through proper window treatment specification.

What blinds are best for thermal insulation?

Cellular honeycomb blinds provide superior thermal insulation through trapped air chambers, followed by multi-layer fabrics, thermal-backed materials, and tight-fitting installations that minimize air infiltration and maximize R-value performance.

Cellular honeycomb blinds offer the best thermal insulation with R-values reaching 2.0-6.0, followed by multi-layer roman shades, insulated roller blinds, and tight-fitting installations that create effective thermal barriers.

Comprehensive Thermal Performance Analysis for Optimal Blind Selection

Thermal insulation effectiveness varies dramatically between blind types, with design characteristics, material properties, and installation methods significantly impacting energy performance and comfort outcomes. My experience with energy-efficient specifications across diverse climate zones provides insights into optimal thermal performance selection criteria.

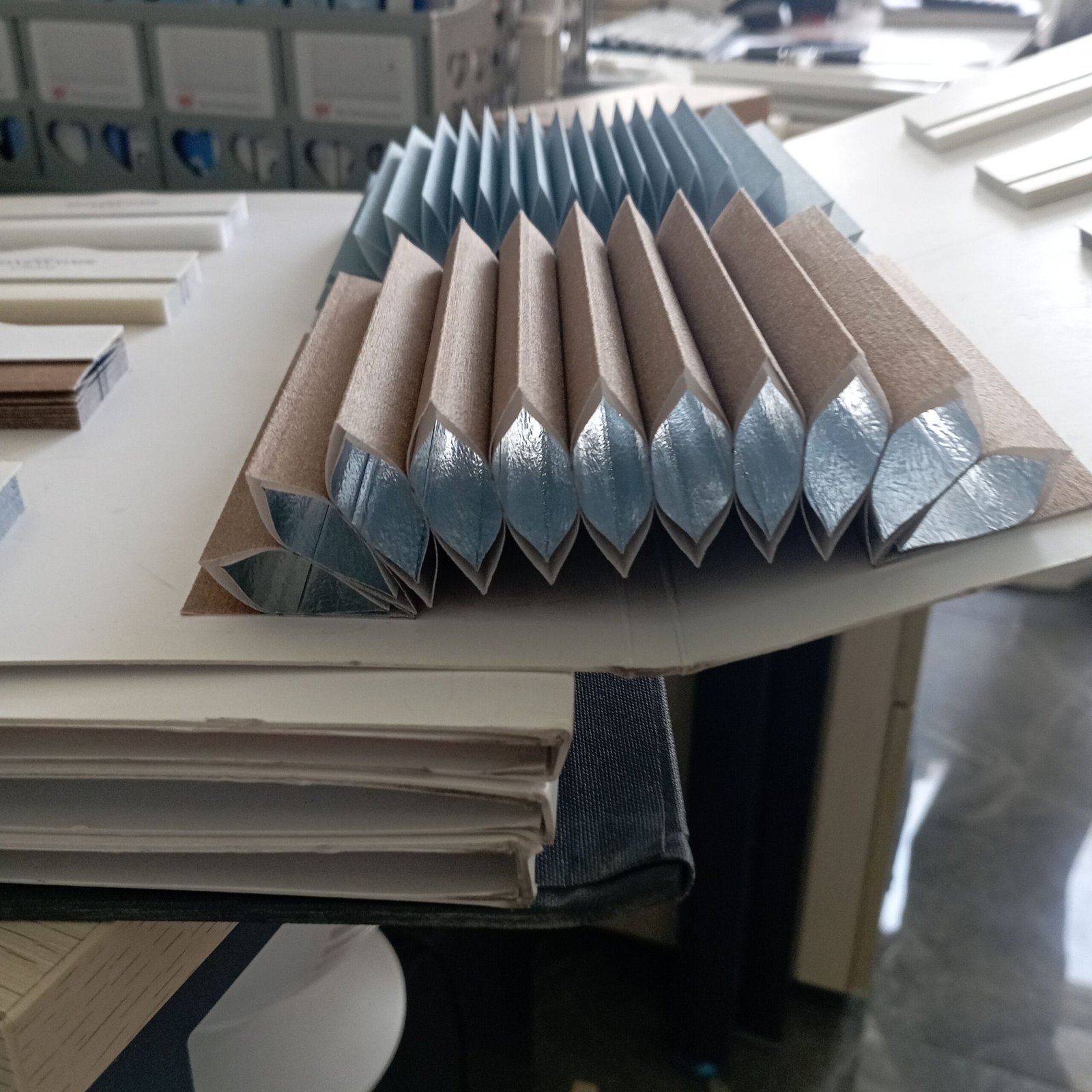

Cellular Honeycomb Design Advantages: Cellular honeycomb blinds achieve superior thermal insulation through trapped air chambers that create effective thermal barriers between interior and exterior environments. Single-cell designs typically achieve R-values of 2.0-3.0, while double-cell configurations reach R-values of 3.5-5.0, and triple-cell premium options can exceed R-6.0 in optimal conditions. The honeycomb structure prevents convective air movement that reduces insulation effectiveness in other blind types, while fabric materials and cell dimensions determine overall thermal performance. Professional-grade cellular blinds utilize low-emissivity coatings and reflective materials that enhance thermal barrier properties beyond basic air trapping mechanisms.

Multi-Layer Fabric Systems: Multi-layer roman shades and layered roller systems provide excellent thermal insulation through fabric combinations that trap air and reflect radiant heat. Thermal-backed fabrics incorporate foam layers, reflective coatings, or specialized insulation materials that achieve R-values of 1.5-3.0 depending on construction methods and material specifications. Blackout fabrics with thermal backing provide dual benefits of light control and insulation performance, making them ideal for energy-efficient applications requiring comprehensive environmental control. Professional installations maximize thermal performance through proper mounting techniques that eliminate air gaps and thermal bridging around window frames.

Material-Specific Thermal Properties: Fabric density, fiber content, and surface treatments significantly impact thermal insulation performance across different blind types. Natural fiber materials including cotton and linen provide moderate insulation through fiber structure and air trapping capabilities, while synthetic materials offer variable performance depending on manufacturing processes and additive treatments. Reflective coatings and metallized surfaces enhance thermal performance by reflecting radiant heat, particularly beneficial in cooling-dominated climates where solar heat gain reduction provides primary energy benefits. Vacuum-metalized films applied to fabric substrates can improve R-values by 20-40% compared to uncoated alternatives.

Installation and Mounting Considerations: Proper installation techniques significantly impact thermal insulation performance through air infiltration control and thermal bridging elimination. Inside mount installations provide superior thermal performance by minimizing air gaps around window frames, while outside mount installations require careful attention to frame sealing and overlap dimensions. Professional mounting systems include thermal breaks, weatherstripping, and sealed track systems that prevent air infiltration that can reduce insulation effectiveness by 30-50% in poorly installed systems. Automated operation systems enable precise positioning for optimal thermal performance throughout daily and seasonal cycles.

| Blind Type | R-Value Range | Primary Insulation Method | Installation Considerations |

|---|---|---|---|

| Single Cell Honeycomb | 2.0-3.0 | Trapped air chambers | Inside mount preferred |

| Double Cell Honeycomb | 3.5-5.0 | Multiple air barriers | Precision fit critical |

| Triple Cell Honeycomb | 5.0-6.0+ | Maximum air trapping | Professional installation |

| Thermal Roller | 1.5-3.0 | Fabric insulation properties | Frame sealing important |

| Multi-layer Roman | 2.0-4.0 | Layered air trapping | Proper mounting essential |

Climate-Specific Performance Optimization: Thermal insulation requirements vary significantly between heating-dominated, cooling-dominated, and mixed climate zones, requiring different optimization strategies for maximum energy efficiency. Heating climates benefit from maximum R-value specifications that reduce heat loss during winter months, while cooling climates require balance between insulation and solar heat gain control. Mixed climates need versatile solutions that provide effective thermal barriers year-round while enabling seasonal operation adjustments for optimal performance. Professional climate analysis determines optimal thermal performance specifications and control strategies for specific geographic locations and building orientations.

Energy Code Compliance and Certification: Energy efficiency codes increasingly require specific thermal performance levels for window treatments in commercial and high-performance residential applications. ASHRAE 90.1 standards specify thermal performance requirements for commercial buildings, while residential energy codes adopt similar requirements for high-efficiency construction. NFRC (National Fenestration Rating Council) certification provides standardized thermal performance ratings that enable accurate comparison between different blind types and manufacturers. Professional specifications should verify energy code compliance and certification requirements for specific applications and jurisdictions.

How much do blinds insulate?

Blind insulation performance ranges from minimal improvement with basic designs to substantial energy savings with high-performance cellular and multi-layer systems. Effective R-values span 0.5-6.0 depending on design, materials, and installation quality.

Blinds provide insulation ranging from R-0.5 for basic designs to R-6.0+ for premium cellular systems, with typical energy savings of 10-25% on heating and cooling costs through reduced heat transfer and air infiltration.

Quantitative Thermal Performance Analysis and Energy Impact Assessment

Blind insulation effectiveness requires quantitative analysis of thermal resistance, air infiltration reduction, and overall energy impact to properly evaluate performance benefits and cost-effectiveness for specific applications. Professional energy modeling and field testing provide accurate performance data for informed specification decisions.

R-Value Performance Ranges and Testing Standards: Thermal resistance (R-value) measurements for blinds follow ASTM C518 and NFRC standards that provide standardized testing conditions and calculation methods for accurate performance comparison. Basic aluminum mini-blinds provide R-values of 0.5-0.8, primarily through air film resistance rather than material properties. Standard fabric roller blinds achieve R-values of 0.8-1.5 depending on fabric density and mounting methods. Single-cell honeycomb blinds typically provide R-values[^1] of 2.0-3.0, while double-cell designs reach R-3.5-5.0, and premium triple-cell configurations can exceed R-6.0 under optimal conditions. However, actual performance varies significantly based on installation quality, air leakage, and operational conditions that may reduce laboratory values by 20-40% in real-world applications.

Air Infiltration Reduction and Sealing Performance: Air infiltration through windows represents 25-40% of total building energy loss, making air sealing capabilities as important as thermal resistance for overall energy performance. Professional-grade blinds with tight-fitting installations can reduce air infiltration by 50-80% compared to bare windows, providing energy benefits that often exceed direct thermal resistance improvements. Cellular blinds with sealed edges and professional mounting systems achieve the highest air infiltration reduction, while loose-fitting installations may provide minimal sealing benefits. Weatherstripping, side channels, and bottom rail sealing significantly impact air infiltration performance and should be included in comprehensive thermal performance[^2] specifications.

Seasonal Energy Savings Analysis: Actual energy savings from blind insulation vary significantly by climate zone, building characteristics, and window orientation, requiring comprehensive analysis for accurate benefit calculation. Heating-dominated climates typically realize 15-30% window-related energy savings from high-performance blinds, while cooling-dominated regions achieve 10-20% savings through reduced solar heat gain and thermal bridging. Mixed climates benefit from year-round performance improvements averaging 12-25% reduction in heating and cooling costs. Professional energy modeling using software such as EnergyPlus or DOE-2 provides accurate savings projections for specific applications and climate conditions.

Window Assembly Thermal Performance Impact: Blind thermal performance must be evaluated as part of complete window assembly systems including frames, glazing, and installation details that affect overall thermal efficiency. Single-pane windows with R-1 glazing realize dramatic improvement from R-3 blinds, effectively tripling window assembly R-value. Double-pane windows with R-3 glazing see more modest but still significant improvement, with R-4 blinds increasing assembly R-value to approximately R-5.5. Triple-pane high-performance windows with R-5+ glazing require careful cost-benefit analysis for blind thermal improvements, as incremental benefits may not justify premium blind specifications in high-performance window applications.

| Climate Zone | Typical Energy Savings | Primary Benefit | Optimal R-Value Range |

|---|---|---|---|

| Heating Dominant | 15-30% | Heat loss reduction | R-4.0-6.0 |

| Cooling Dominant | 10-20% | Solar heat gain control | R-2.0-4.0 |

| Mixed Climate | 12-25% | Year-round efficiency | R-3.0-5.0 |

| Extreme Climate | 20-35% | Maximum thermal barrier | R-5.0-6.0+ |

Professional Testing and Verification Methods: Thermal performance verification requires standardized testing methods and professional measurement techniques that provide accurate data for energy analysis and code compliance. Laboratory testing following NFRC procedures provides baseline performance data under controlled conditions, while field testing using infrared thermography and heat flux measurements validates real-world performance. Professional energy audits can quantify actual energy savings through utility bill analysis and thermal imaging assessment of installed systems. Continuous monitoring systems enable optimization of blind operation for maximum energy efficiency throughout seasonal cycles.

Cost-Effectiveness Analysis and Payback Periods: Thermal performance benefits must be evaluated against specification cost premiums to determine optimal value propositions for different applications. Basic thermal improvements typically achieve 5-10 year payback periods through energy savings, while premium high-R-value specifications may require 8-15 years for full cost recovery. However, comfort improvements, property value enhancement, and utility rebate programs can significantly improve payback calculations beyond direct energy savings. Professional financial analysis should include all benefit categories and available incentive programs for accurate cost-effectiveness evaluation.

What is the R-value of blinds?

Blind R-values range from 0.5 for basic aluminum mini-blinds to over 6.0 for premium triple-cell honeycomb designs. Most commercial applications utilize blinds with R-values between 2.0-4.0 for optimal cost-effectiveness and thermal performance.

Blind R-values typically range from R-0.5 for basic metal blinds to R-6.0+ for premium cellular designs, with most commercial applications specifying R-2.0-4.0 blinds for optimal thermal performance and cost-effectiveness balance.

Detailed R-Value Analysis and Professional Specification Guidelines

R-value specifications require understanding of testing standards, performance variables, and application-specific requirements that determine optimal thermal resistance levels for cost-effective energy efficiency improvements. Professional specification decisions must balance thermal performance, cost considerations, and practical installation requirements.

R-Value Testing Standards and Measurement Methods: NFRC 100 provides the primary testing standard for window treatment thermal resistance, utilizing guarded hot plate testing methods that measure heat transfer through complete blind assemblies under standardized conditions. Testing procedures account for convective, conductive, and radiative heat transfer mechanisms that affect real-world thermal performance. Standard test conditions include 70°F interior temperature, 0°F exterior temperature, and 15 mph wind speeds that simulate typical winter heating conditions. However, actual R-values may vary by ±20% depending on installation quality, air leakage, and environmental conditions that differ from laboratory testing parameters.

Material and Design Factors Affecting R-Values: Cellular honeycomb designs achieve high R-values through trapped air chambers that minimize convective heat transfer, with cell depth, number of cells, and fabric properties determining overall thermal resistance. Single-cell designs with 3/8" depth typically achieve R-2.0-2.5, while 3/4" cells reach R-2.5-3.0 depending on fabric specifications. Double-cell configurations effectively double R-values through additional air chambers, with 3/8" double-cells achieving R-3.5-4.0 and 3/4" double-cells reaching R-4.5-5.0. Triple-cell premium designs can exceed R-6.0 with optimal fabric selections and precision manufacturing that minimizes thermal bridging through cell walls.

Fabric Properties and Thermal Enhancement: Fabric materials significantly impact R-value performance through density, fiber content, and surface treatments that affect thermal conductivity and radiant heat transfer. Low-emissivity coatings reduce radiant heat transfer by 15-25%, while reflective metallized surfaces can improve R-values by 20-30% compared to standard fabric alternatives. Fabric thickness and density provide additional thermal resistance, with heavier fabrics generally achieving higher R-values through increased thermal mass and reduced air movement. However, fabric selection must balance thermal performance with light transmission, durability, and aesthetic requirements for complete specification optimization.

Installation Impact on R-Value Performance: Installation methods significantly affect actual R-value performance through air leakage control and thermal bridging elimination that can reduce laboratory ratings by 20-50% in poorly executed installations. Inside mount installations typically provide 10-20% higher effective R-values compared to outside mount alternatives through reduced air infiltration and thermal bridging around window frames. Professional mounting systems with weatherstripping, side channels, and sealed tracks maximize R-value performance while preventing air leakage that compromises thermal efficiency. Proper measurement and precision installation are critical for achieving rated thermal performance in field applications.

| Blind Configuration | Laboratory R-Value | Typical Field R-Value | Performance Factors |

|---|---|---|---|

| Basic Mini-Blind | R-0.5-0.8 | R-0.4-0.6 | Minimal thermal resistance |

| Single Cell 3/8" | R-2.0-2.5 | R-1.6-2.0 | Installation quality critical |

| Double Cell 3/8" | R-3.5-4.0 | R-2.8-3.2 | Professional installation |

| Double Cell 3/4" | R-4.5-5.0 | R-3.6-4.0 | Premium performance |

| Triple Cell Premium | R-6.0+ | R-4.8-5.5 | Maximum thermal resistance |

Climate-Specific R-Value Requirements: Optimal R-value specifications vary significantly by climate zone, building type, and energy efficiency objectives that determine cost-effective thermal performance levels. Heating-dominated climates benefit from maximum R-value specifications (R-4.0-6.0+) that reduce winter heat loss and improve comfort during cold periods. Cooling-dominated regions require balanced approach considering solar heat gain control alongside thermal resistance, with R-2.0-4.0 typically providing optimal cost-effectiveness. Mixed climates benefit from moderate R-value specifications (R-3.0-5.0) that provide year-round energy efficiency without excessive cost premiums for marginal performance gains.

Professional Specification and Code Compliance: Energy efficiency codes increasingly specify minimum R-value requirements for window treatments in high-performance commercial and residential applications. ASHRAE 90.1 standards for commercial buildings may require specific thermal performance levels depending on climate zone and building classification. Residential energy codes such as IECC and state-specific requirements adopt similar thermal performance standards for energy-efficient construction. Professional specifications must verify applicable R-value requirements and ensure selected blinds meet or exceed minimum code standards for permit approval and energy compliance certification. Utility rebate programs often require specific R-value thresholds for incentive eligibility, making code compliance analysis essential for project economics and energy efficiency objectives.

What is the R-value of honeycomb blinds?

Honeycomb blind R-values range from R-2.0 for basic single-cell designs to R-6.0+ for premium triple-cell configurations. Double-cell honeycomb blinds typically achieve R-3.5-5.0, representing the optimal balance of thermal performance and cost-effectiveness for most applications.

Honeycomb blind R-values span R-2.0-6.0+ depending on cell configuration, with single-cell designs achieving R-2.0-3.0, double-cell reaching R-3.5-5.0, and premium triple-cell configurations exceeding R-6.0 for maximum thermal efficiency.

Advanced Honeycomb Thermal Performance Analysis and Optimization Strategies

Honeycomb blind thermal performance depends on cellular geometry, fabric properties, manufacturing precision, and installation quality that determine actual R-value achievement in field applications. Professional specification requires understanding these performance variables for optimal thermal efficiency and cost-effectiveness.

Cellular Design Geometry and Thermal Physics: Honeycomb cellular structure creates trapped air chambers that provide thermal resistance through minimized convective heat transfer and reduced thermal bridging. Single-cell designs utilize one air chamber per fabric layer, with thermal resistance proportional to cell depth and fabric thermal properties. Cell depths of 3/8" typically achieve R-2.0-2.5, while 3/4" cells reach R-2.5-3.0 through increased air trapping volume. Double-cell configurations create two isolated air chambers that effectively double thermal resistance through additional convective barriers, achieving R-3.5-4.0 for standard depths and R-4.5-5.0 for deeper cell configurations. Triple-cell premium designs add a third air chamber for maximum thermal resistance, reaching R-6.0+ under optimal conditions with specialized fabric materials and precision manufacturing.

Manufacturing Quality and Thermal Bridging Control: Precision manufacturing significantly impacts honeycomb blind R-value performance through thermal bridging control and air chamber sealing that prevents convective heat transfer. High-quality manufacturing utilizes ultrasonic welding or thermal bonding techniques that create hermetic seals between cell walls without thermal bridging through adhesives or mechanical fasteners. Thermal bridging through cell walls can reduce R-values by 15-30% compared to theoretical performance, making manufacturing quality critical for specified thermal performance achievement. Professional-grade honeycomb blinds incorporate thermal breaks and minimal bridging designs that maximize air chamber effectiveness and overall thermal resistance.

Fabric Selection and Thermal Enhancement Technologies: Fabric materials and surface treatments significantly impact honeycomb blind R-value performance beyond basic cellular geometry contributions. Standard polyester fabrics provide baseline thermal performance, while specialized thermal fabrics incorporate insulating fibers, reflective coatings, or low-emissivity treatments that enhance R-values by 20-40% compared to basic materials. Metallized fabric surfaces reflect radiant heat transfer, particularly beneficial in cooling applications where solar heat gain control provides primary energy benefits. Multi-layer fabric constructions combine insulating properties with reflective treatments for maximum thermal performance in premium honeycomb applications.

Installation Variables Affecting Actual R-Value Performance: Installation quality significantly impacts honeycomb blind thermal performance through air leakage control and proper mounting that maintains cellular structure integrity. Inside mount installations provide superior thermal performance by minimizing air gaps around window frames that can reduce effective R-values by 20-30% compared to laboratory testing conditions. Professional mounting systems include side channels, weatherstripping, and sealed tracks that prevent air infiltration while maintaining cellular structure under operational stresses. Improper installation can compress cellular structure, create air leakage paths, or introduce thermal bridging that substantially reduces thermal performance below manufacturer specifications.

| Cell Configuration | Cell Depth | Typical R-Value | Optimal Applications |

|---|---|---|---|

| Single Cell | 3/8" | R-2.0-2.5 | Basic thermal improvement |

| Single Cell | 3/4" | R-2.5-3.0 | Moderate performance needs |

| Double Cell | 3/8" | R-3.5-4.0 | Standard high-performance |

| Double Cell | 3/4" | R-4.5-5.0 | Premium thermal efficiency |

| Triple Cell | 3/4"+ | R-6.0+ | Maximum performance applications |

Performance Optimization and Control Strategies: Honeycomb blind thermal performance can be optimized through proper operation and control strategies that maximize R-value benefits throughout daily and seasonal cycles. Fully closed positions provide maximum thermal resistance, while partial opening reduces R-values proportionally to open area percentage. Automated control systems enable optimization of thermal performance by maintaining closed positions during peak heating or cooling load periods while providing natural light and view access during optimal conditions. Seasonal operation strategies maximize heating season thermal resistance while enabling cooling season ventilation and solar heat gain control as appropriate for climate conditions.

Field Testing and Performance Verification: Actual honeycomb blind R-value performance requires field verification through thermal imaging, heat flux measurements, and energy monitoring that validate laboratory specifications under real-world conditions. Infrared thermography reveals thermal bridging, air leakage, and installation defects that reduce thermal performance below rated values. Heat flux sensors provide quantitative measurement of thermal resistance under actual environmental conditions and operation patterns. Professional commissioning should include thermal performance verification and optimization of control strategies for maximum energy efficiency achievement throughout building operation cycles.

What R-value insulation do I need?

R-value requirements depend on climate zone, building type, energy efficiency objectives, and window characteristics. Most commercial applications require R-2.0-4.0 blinds, while high-performance buildings may specify R-4.0-6.0+ for maximum thermal efficiency.

Required R-values vary by climate zone from R-2.0-3.0 in mild climates to R-4.0-6.0+ in extreme climates, with commercial applications typically specifying R-3.0-5.0 for optimal energy efficiency and cost-effectiveness balance.

Climate-Specific R-Value Determination and Professional Specification Guidelines

R-value requirements require comprehensive analysis of climate conditions, building characteristics, energy efficiency objectives, and cost-effectiveness considerations that determine optimal thermal performance specifications for specific applications. Professional analysis ensures appropriate thermal resistance levels for maximum energy efficiency and comfort benefits.

Climate Zone Analysis and Thermal Load Calculations: Climate zone classification provides the foundation for R-value requirement determination through heating degree days (HDD), cooling degree days (CDD), and extreme temperature analysis that quantify thermal loads and insulation benefits. ASHRAE Climate Zone 1-2 (hot climates) typically require R-2.0-3.0 blinds focused on solar heat gain control rather than maximum thermal resistance. Climate Zone 3-4 (mixed climates) benefit from R-3.0-4.0 specifications that provide year-round energy efficiency without excessive cost premiums. Climate Zone 5-6 (cold climates) require R-4.0-5.0 blinds for effective winter heating load reduction and comfort improvement. Climate Zone 7-8 (very cold/subarctic) may justify R-5.0-6.0+ specifications for maximum thermal performance in extreme conditions. Professional thermal load calculations using ASHRAE methods provide precise R-value requirements for specific buildings and orientations.

Building Type and Occupancy Considerations: Different building types require varying R-value specifications based on occupancy patterns, internal loads, and energy efficiency objectives that affect optimal thermal performance levels. Commercial office buildings typically require R-3.0-4.0 blinds that balance energy efficiency with daylighting and view requirements for occupant productivity. Healthcare facilities benefit from R-4.0-5.0 specifications that provide superior thermal comfort for patient care areas while reducing energy costs through improved thermal performance. Educational buildings require R-3.0-5.0 blinds depending on climate zone and budget considerations, with higher R-values justified in extreme climates or high-performance construction projects. Residential applications typically specify R-2.0-4.0 blinds based on climate conditions and homeowner energy efficiency priorities.

Window Performance Integration and Assembly R-Values: Blind R-value requirements must consider existing window performance characteristics and overall assembly thermal resistance objectives for optimal cost-effectiveness and energy performance. Single-pane windows with R-1 glazing realize dramatic benefits from high R-value blinds, with R-4 blinds effectively quintupling assembly thermal resistance to approximately R-5. Double-pane windows with R-3 glazing benefit significantly from R-3-4 blinds that increase assembly R-value to R-5.5-6.5 for substantial energy improvements. Triple-pane high-performance windows with R-5+ glazing require careful cost-benefit analysis for premium blind specifications, as incremental thermal benefits may not justify cost premiums in already high-performance window assemblies.

Energy Code Requirements and Compliance Analysis: Building energy codes increasingly specify minimum thermal performance requirements for window assemblies that include window treatment contributions to overall thermal resistance. IECC residential energy code may require specific assembly R-values that necessitate high-performance blind specifications for code compliance. ASHRAE 90.1 commercial standards specify thermal performance requirements based on climate zone and building type that affect blind R-value specifications. State and local energy codes may impose more stringent requirements than national standards, requiring professional code analysis for accurate compliance determination. Green building certification programs such as LEED often require enhanced thermal performance beyond minimum code requirements.

| Application Type | Climate Zone 1-2 | Climate Zone 3-4 | Climate Zone 5-6 | Climate Zone 7-8 |

|---|---|---|---|---|

| Residential | R-2.0-3.0 | R-3.0-4.0 | R-4.0-5.0 | R-5.0-6.0+ |

| Commercial Office | R-2.0-3.0 | R-3.0-4.0 | R-4.0-5.0 | R-5.0-6.0+ |

| Healthcare | R-3.0-4.0 | R-4.0-5.0 | R-5.0-6.0+ | R-6.0+ |

| Educational | R-2.0-3.0 | R-3.0-4.0 | R-4.0-5.0 | R-5.0-6.0+ |

Cost-Benefit Analysis and Payback Calculations: R-value requirement determination must include comprehensive cost-benefit analysis that evaluates thermal performance benefits against specification cost premiums for optimal value proposition achievement. Basic thermal improvements (R-2.0-3.0) typically achieve 5-8 year payback periods through energy savings, making them cost-effective for most applications. Moderate performance specifications (R-3.0-4.0) provide 6-10 year payback periods with additional comfort benefits that enhance value propositions. High-performance specifications (R-4.0-6.0+) may require 8-15 year payback periods but provide maximum energy savings and comfort benefits that justify investment in extreme climates or high-performance buildings. Professional financial analysis should include utility rebates, tax incentives, and comfort value quantification for accurate payback calculations.

Professional Design and Specification Services: Optimal R-value determination requires professional analysis of climate conditions, building characteristics, energy efficiency objectives, and cost considerations that ensure appropriate thermal performance specifications. Energy modeling software such as EnergyPlus or eQUEST provides accurate thermal load analysis and R-value benefit quantification for specific applications. Professional commissioning includes thermal performance verification and optimization of control strategies for maximum energy efficiency achievement. Ongoing performance monitoring enables R-value requirement refinement through actual energy usage analysis and thermal performance measurement under real-world operating conditions.

Conclusion

Thermal insulation standards for blinds require understanding R-values, testing methods, and climate-specific requirements to achieve optimal energy efficiency, comfort, and cost-effectiveness through professional specification and installation practices.

Extended FAQ Section

How do thermal blinds compare to upgrading windows for energy efficiency?

Thermal blinds provide cost-effective energy efficiency improvements compared to window replacement, typically costing 80-90% less while achieving 40-70% of the thermal performance benefits of new high-performance windows. Window replacement projects average $300-800 per window for double-pane upgrades and $500-1200 for triple-pane high-performance units, while premium thermal blinds cost $50-200 per window for comparable energy savings in many applications. Thermal blinds with R-4.0-5.0 performance can transform single-pane R-1 windows into R-5-6 assemblies, approaching the performance of new double-pane windows at a fraction of the cost. However, window replacement provides additional benefits including improved air sealing, reduced condensation, enhanced security, and noise reduction that thermal blinds cannot address. Professional energy analysis should compare lifecycle costs, energy savings, comfort improvements, and additional benefits to determine optimal improvement strategies. Retrofit applications often benefit from thermal blind installations as immediate energy efficiency improvements while planning future window replacement projects. New construction projects should evaluate integrated window and blind specifications for maximum energy performance and cost-effectiveness. Utility rebate programs may favor window replacement over blind upgrades, requiring financial analysis of available incentives for optimal project economics. Geographic climate conditions significantly impact the relative value proposition, with extreme climates potentially justifying window replacement while moderate climates favor thermal blind approaches. Professional thermal modeling provides accurate comparison of energy savings, comfort improvements, and cost-effectiveness for specific applications and climate conditions.

What maintenance is required to preserve thermal insulation performance?

Thermal blind insulation performance requires minimal maintenance beyond regular cleaning and periodic inspection to ensure continued R-value effectiveness and energy efficiency benefits throughout the product lifecycle. Cellular honeycomb blinds maintain thermal performance indefinitely without degradation as long as cellular structure remains intact and air chambers stay sealed from damage or contamination. Regular cleaning using vacuum brush attachments removes dust accumulation that can reduce thermal performance by blocking air chambers or affecting fabric properties, with monthly cleaning recommended for optimal performance maintenance. Professional ultrasonic cleaning annually helps remove embedded dirt and allergens while preserving cellular structure and thermal properties without damage risks from aggressive cleaning methods. Fabric inspection should identify any tears, holes, or separation that could compromise air chamber integrity and reduce thermal resistance, with professional repair services available for minor damage correction. Operating mechanism maintenance includes lubrication of lift cords, tracks, and motor systems that ensure proper operation for optimal thermal positioning throughout daily cycles. Control system calibration maintains automated positioning accuracy that maximizes thermal performance during peak heating and cooling periods while providing appropriate daylighting and view access. Installation hardware inspection verifies mounting security and weatherstripping effectiveness that prevents air infiltration and maintains thermal barrier integrity around window frames. Professional maintenance contracts typically include annual inspection, cleaning, adjustment, and performance verification services that ensure continued thermal efficiency and warranty compliance. Documentation maintenance requires tracking thermal performance certifications, warranty coverage, and maintenance records for building energy compliance and insurance coverage validation throughout the installation lifecycle.

How do smart controls optimize thermal insulation performance?

Smart controls optimize thermal blind insulation performance through automated positioning, environmental monitoring, and predictive algorithms that maximize energy efficiency while maintaining occupant comfort and natural light access throughout daily and seasonal cycles. Advanced control systems integrate weather data, building management systems, and occupancy sensors to determine optimal blind positions for thermal performance based on real-time conditions and energy demand patterns. Thermal optimization algorithms consider exterior temperature, solar angle, interior temperature targets, and HVAC system operation to position blinds for maximum energy efficiency during peak heating and cooling periods. Occupancy-based controls ensure thermal performance optimization during unoccupied periods while providing appropriate light and view access when spaces are occupied, typically achieving 15-25% additional energy savings compared to manual operation. Seasonal programming automatically adjusts thermal optimization strategies for heating versus cooling seasons, maximizing winter heat retention and summer solar heat gain control through position and timing adjustments. Integration with building automation systems enables coordinated operation with HVAC, lighting, and other building systems for comprehensive energy management and comfort optimization. Weather forecast integration provides predictive control that pre-positions blinds for anticipated thermal loads, improving system efficiency and occupant comfort through proactive rather than reactive thermal management. Zone-based control systems optimize thermal performance for different building orientations, spaces, and occupancy patterns that require customized thermal management strategies for maximum energy efficiency. Professional commissioning of smart control systems includes thermal performance testing, algorithm optimization, and occupancy pattern analysis that ensures maximum energy savings achievement. Monitoring and analytics capabilities provide ongoing performance feedback and optimization opportunities that maintain peak thermal efficiency throughout changing building conditions and occupancy patterns.

Maximize Your Project’s Energy Efficiency Today

Stop losing money through poor thermal performance. Our thermal insulation specialists provide comprehensive R-value analysis, certified performance testing, and professional installation services that maximize energy savings and comfort.

Request detailed thermal performance analysis, R-value specifications, and energy savings projections by contacting info@velablinds.com today.

---

[^1]: Understanding R-values is crucial for selecting energy-efficient window treatments that minimize energy waste and enhance comfort.

[^2]: Learn about the importance of thermal performance in window treatments and how it affects energy efficiency and comfort in buildings.Partner with VelaBlinds for Your Next Project

Smart window treatments shouldn’t be complicated. After working with 500+ distributors and contractors worldwide, I’ve streamlined the process to get you quality products, competitive pricing, and reliable support – every time.

Why project professionals choose VelaBlinds:

- ✅ Fast, Accurate Quotes – Detailed specs and pricing within 24 hours

- ✅ Transparent Pricing – No hidden fees, volume discounts clearly outlined

- ✅ Quality Assurance – Direct partnerships with certified OEM manufacturers

- ✅ Project Support – Dedicated account manager from quote to delivery

Start your next project:

📧 Quick Quote: Send your requirements to info@velablinds.com

📱 Direct Contact: WhatsApp +86 137 2012 8317

🌐 Browse Solutions: https://velablinds.com/

📁 Product Resources: Access spec sheets, catalogs & project files

Jimmy Chen, Founder

"I built VelaBlinds to solve the real challenges I faced as a project buyer – long lead times, unclear specs, and unreliable suppliers. Let’s discuss how we can power your projects with smarter blinds."

Serving distributors and contractors across North America, Europe, and Australia since 2018.